Everything You Wanted to Know About Propellers But Were Afraid to Ask

By Rick Mackie, Former Mercury Racing’s Sr. Marketing Manager

You’ve heard the analogies before. Propellers on a boat are similar to tires on a car. When a tire loses its tread, traction is directly affected. The tire loses its grip and slips or spins when power is applied abruptly or when under force in a hard turn. Wet road conditions and loose gravel affect worn tires even more, making them inefficient as they slip and spin before gripping the road. The misapplication of tires can adversely affect car performance as well. A sports car tread isn’t going to provide near the traction on a SUV as an off-road tire with a tread and physical dimensions designed specifically for that application. Similarly, an off-road tire tread design is going to be inefficient on a sports car designed for quick acceleration and high speed operation on smooth asphalt roadways.

Like tires in the automotive world, propellers on a boat are second in importance only to the power available from the engine. Without propeller thrust, nothing happens. Props affect every phase of performance – hole shot, acceleration, top-end speed, handing, ride, engine life, fuel economy and safety. The right or wrong propeller selection can make or break a boat’s performance

HOW THEY WORK

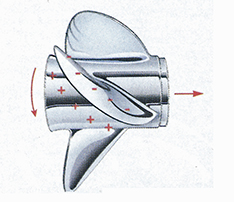

A typical right-hand rotation propeller blade rotates clockwise, top to bottom. As the blade moves down, it pushes water down and back, similar to a swimmer’s hand. At the same time, water rushes in behind the blade to fill the space left by the downward moving blade. The result is a pressure differential between the two sides of the blade. A positive pressure or pushing effect builds on the underside of the blade and a negative pressure (pulling effect) builds on the top side of the blade. The result? The propeller is both pushed and pulled through the water, creating thrust or momentum.

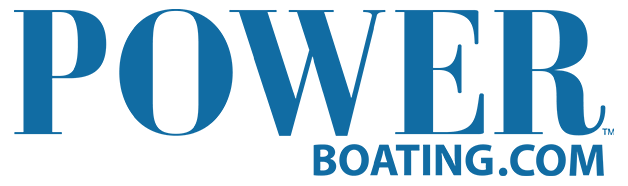

The pressure causes water to be drawn into the propeller from the front and accelerate out the back – similar to how a household fan pulls air from behind it and blows it forward, circulating air in a room. There are a variety of terms used to describe propeller characteristics and performance attributes. Diameter is the circle made across the blade tips as the propeller rotates. The proper diameter for a specific application is determined by engine power and its RPM operating range. Gear ratio, boat weight, hull configuration and the degree to which the propeller may operate in a partially surfaced condition also play a role in determining diameter. With all other variables remaining constant, diameter will be increased as power increases and as the propeller is raised to higher (surfacing) operating conditions.

PROPELLER CHARACTERISTICS

PITCH

Pitch is the distance a propeller would move in one revolution if it were moving through a soft solid such as a screw in wood.

For example, a 17-1/2” x 23” Mercury Racing 4-blade sterndrive propeller has a 17-1/2” with 23” of pitch. Theoretically, this propeller would move forward 23” in one revolution. Pitch is measure on the face of the blade.

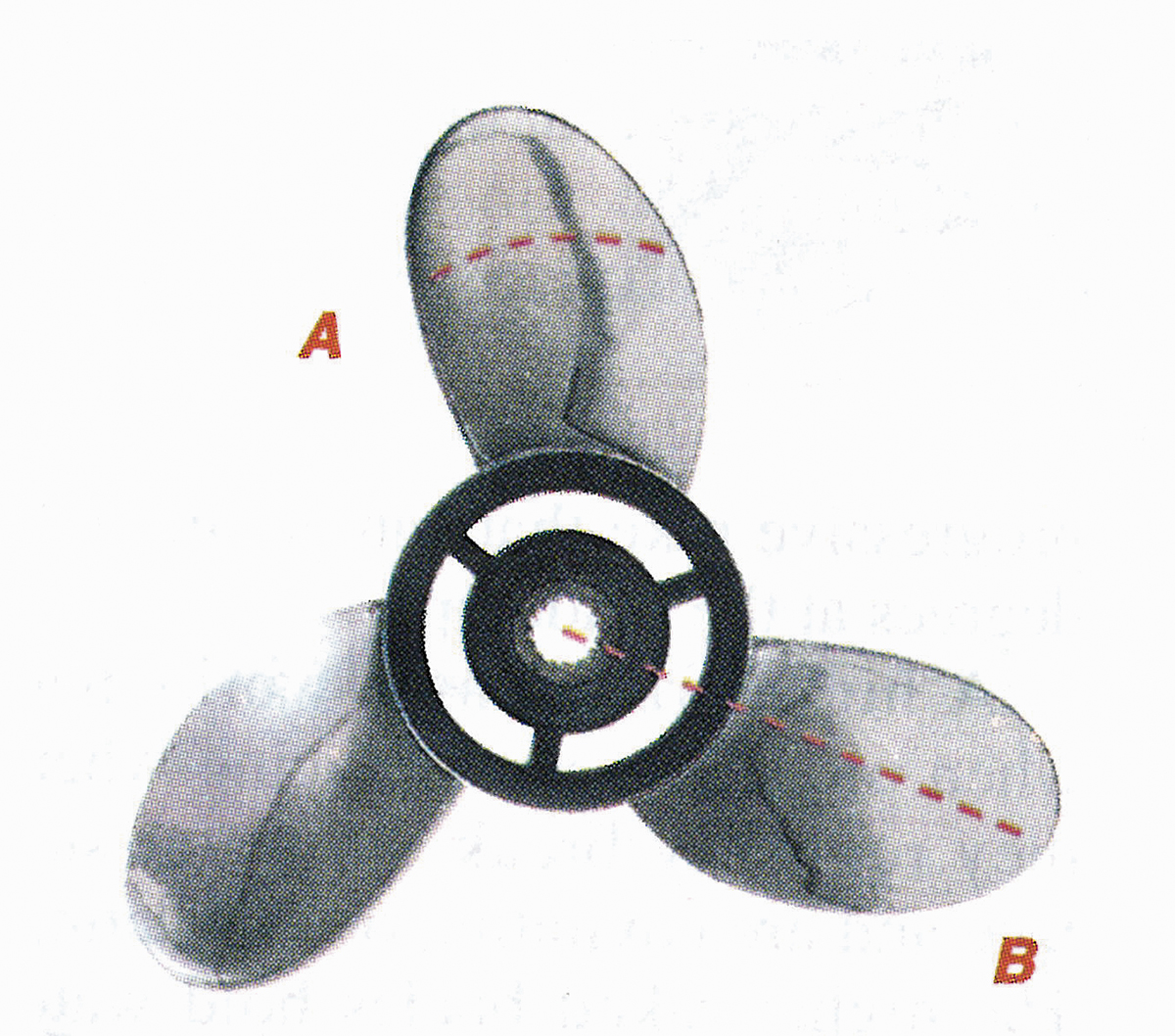

B-Propeller rake line.

There are two common types of pitch – constant or true pitch and progressive pitch. Constant pitch props have the same pitch from the leading edge to the trailing edge of the blade face. Progressive pitch, also known as blade camber, starts low at the leading edge and progressively increases to the trailing edge. The pitch number assigned is the average pitch over the entire blade.

Pitch is like having another set of gears and has a direct effect on engine RPM. The lower the pitch, the higher the engine RPM. Pitch must be carefully selected to ensure good hole shot and acceleration without jeopardizing engine life by spinning it too high or beyond the recommended RPM range at wide open throttle.

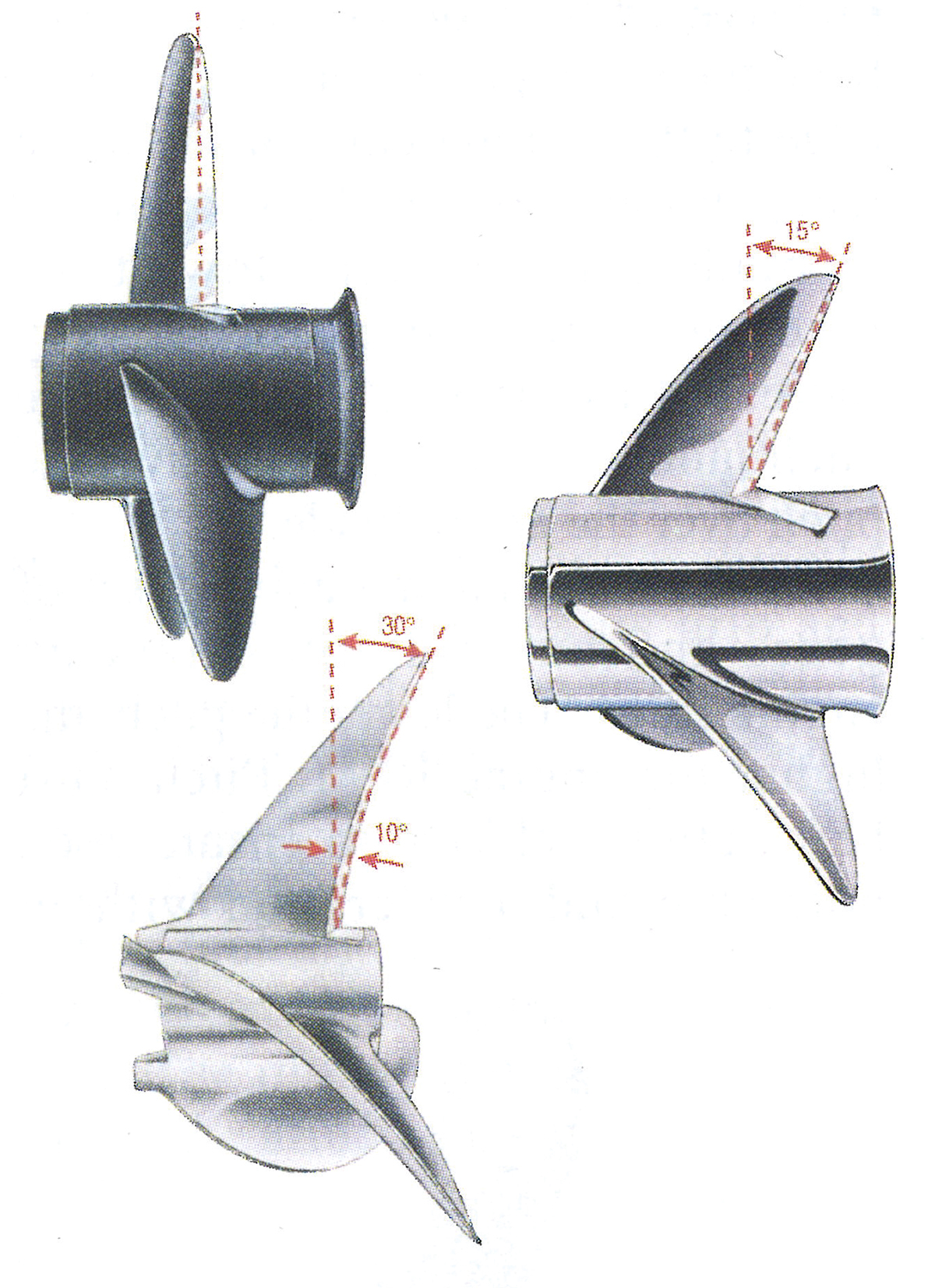

Rake is the angle of the trailing edge of the propeller blade relative to an imaginary line that is perpendicular to the propeller hub. The greater that angle, the greater the rake.

Basic propellers for outboards and sterndrives have 15-degree rake. High performance propellers have a progressive rake that can go up to 30 degrees at blade tip.

A higher rake angle works best when propellers are surfacing where they regularly break the water surface and are cavitating or ventilating. The higher raked blades hold water longer before it is thrown off into the air by centrifugal force. Higher rake also helps create bow life on lighter, faster boats with higher outboard or sterndrive transom heights.

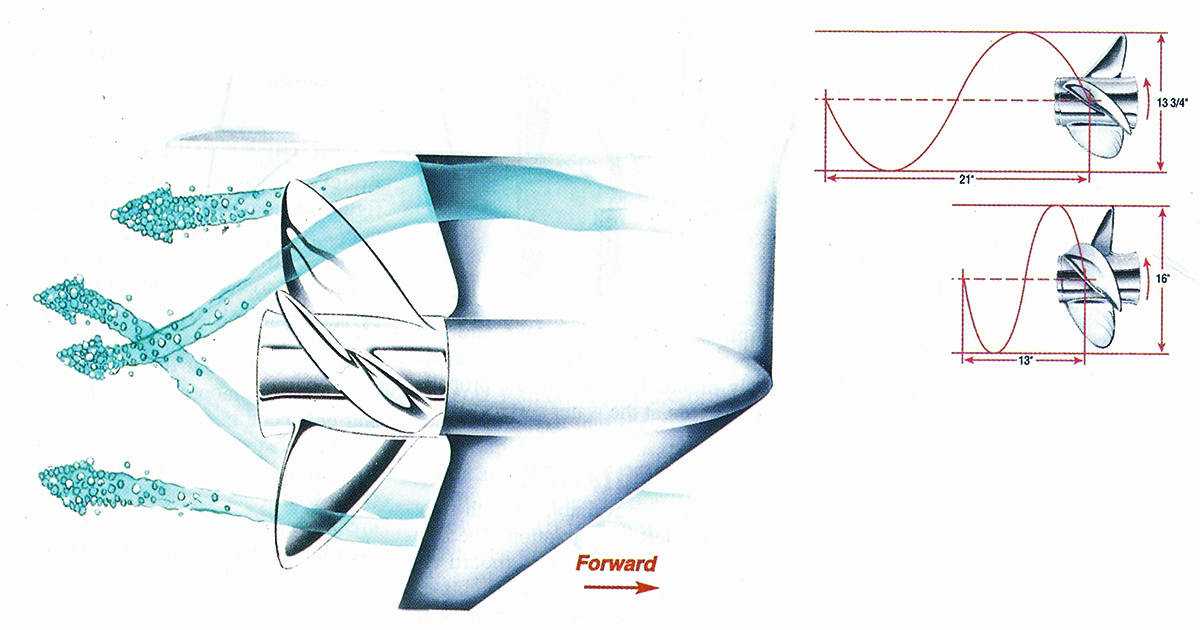

CUPPING

Most high performance propellers are cast with an edge curl or “cup” on the trailing edge. Cupping produces many of the same benefits realized by progressive pitch and curved or higher rakes. Cupping a prop can reduce full throttle engine speed 150-300 rpm below the same propeller without cup. Similar to the higher rake and progressive pitches, cupping is beneficial only in situations where the propeller will be run at the water surface.

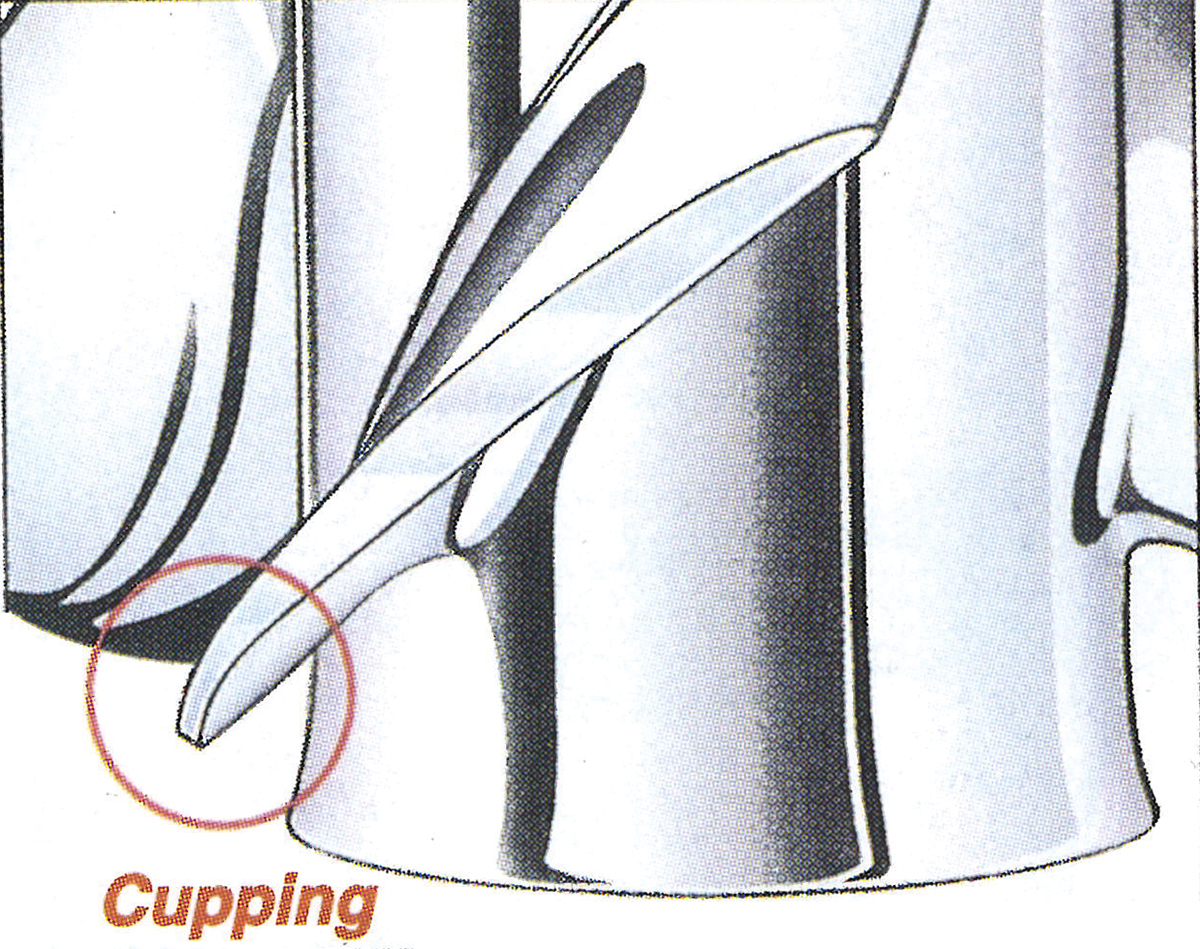

ROTATION

Propellers are available in both right hand and left-hand rotation. The standard rotation for both outboard and sterndrive engines is right-hand. Left hand or counter-rotation models are available for multiple engine applications. The counter-rotation engine with a left-hand rotation propeller counters the steering torque caused by the right hand rotation engine. To tell if a propeller is right or left-hand, place it on the hub (top or bottom). Right-hand blades should be slanting from the lower left to the upper right. The opposite is true for a left-hand propeller. A right-hand rotation propeller has the same basic blade slope as the threads on a common right-hand screw. When running on an engine, right-hand rotation propellers turn clockwise. The rotation of propellers on multiple engine rigs can have a profound effect on the performance of the boat. V-bottom hulls and catamaran hulls call for different rotations, depending on the size, weight and other certain boat characteristics.

NUMBER OF BLADES

Believe it or not, if someone could figure out how to get around vibration, a single-blade propeller would be the most efficient. Since the vibration issue is yet to be resolved, a two-blade prop is the most efficient. In general, efficiency suffers as the number of blades is added but the reduction of vibration and smooth engine operation and enhanced boat handing is worth it. The most common propeller configurations today are three, four and five-blade. Four and five-blade props are the most popular today in both high performance and racing applications where outboards and sterndrives are being run at increased heights. Vibrations are kept at a minimal level while the added blades enhance acceleration and help to lift the bow for added speed.

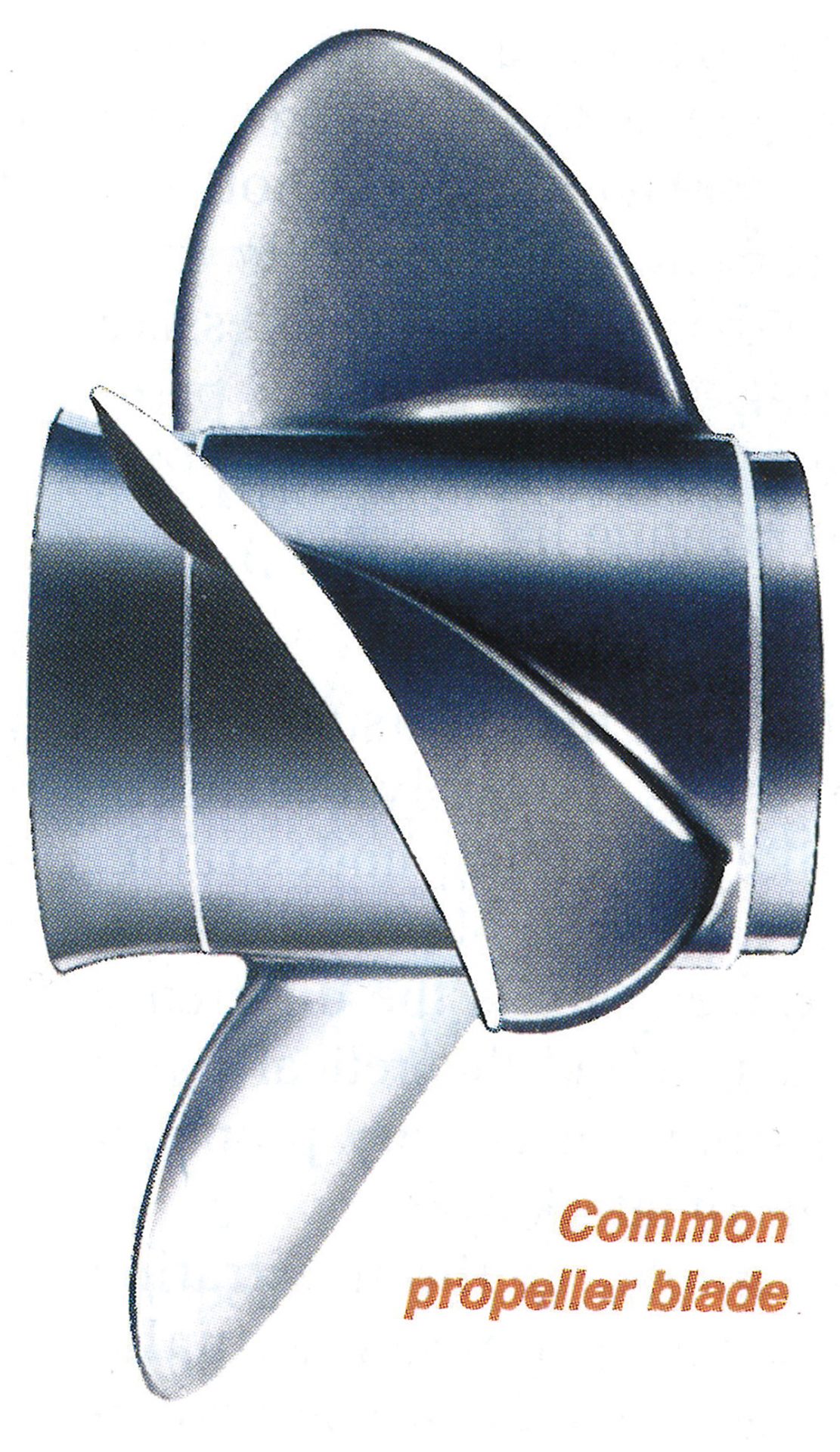

BLADE CONTOUR

Contour is the shape of the blades as viewed from directly over the blade face or back. The blade face is either rounded (round ear) or shaped with a straight trailing edge (cleaver).

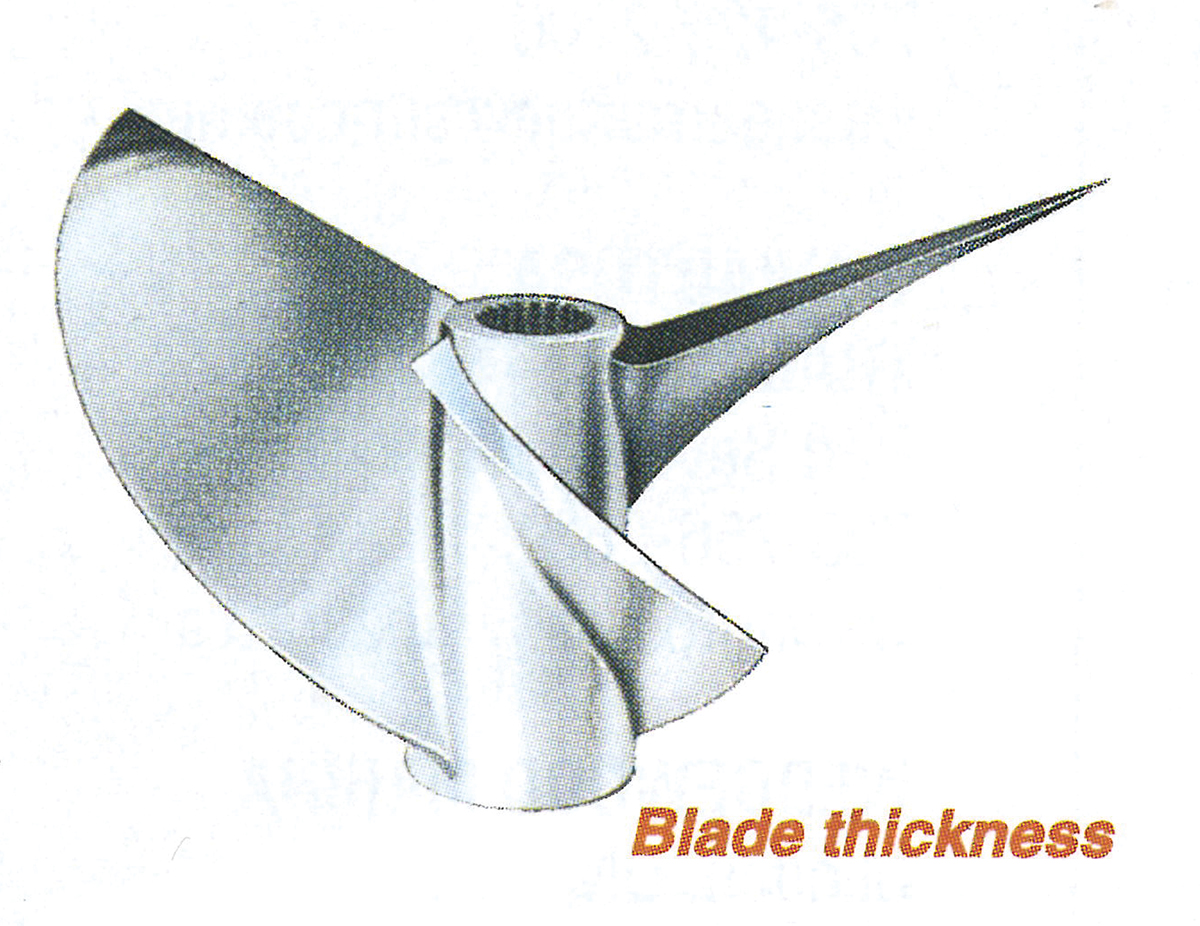

BLADE THICKNESS

A Propeller blade is thickest at the point where it meets the hub. It becomes thinner as it moves away from the hub toward the tip. The reason for this is that the forces are greatest at the hub and gradually reduced as you move out toward the tip of the blade. Blade thicknesses should be as thin as possible for enhanced efficiency, yet maintaining maximum strength. Thickness is determined, in part, by the casting material. The cleaver blade shape works best for propellers which are run partially surfaced.

The wedge blade cross section is both strong and efficient for surfacing outboards and sterndrives.

CAVITATION/SLIP

As the gearcase and propeller pass through water at an increasing speed, the pressure that holds the water to the sides and back of their shapes is reduced. Depending on water temperature, when the pressure reaches a sufficiently low level, boiling or the formation of water vapor occurs. With propellers, this takes place at the leading edge of the blades. When speed is reduced and the pressure goes up, boiling subsides. As the water vapor bubble move downstream into a higher-pressure region that won’t sustain boiling, they collapse (condense back to liquid.) The collapsing action or implosion of the bubbles release energy that chips away at the blades causing a cavitation burn or erosion of the metal. Initial cause of cavitation may include nicks in the leading edge, too much cup, sharp leading edge corners, improper polishing, or poor blade design

ANGLE OF ATTACK

propeller blade works similarly to how an airplane wing functions. As it travels through air, a negative pressure is created on top of the wing and a positive pressure on the bottom. The faster the plane travels in a straight line, the greater the pressure differential, with the positive pressure overtaking the negative pressure, thus creating lift.

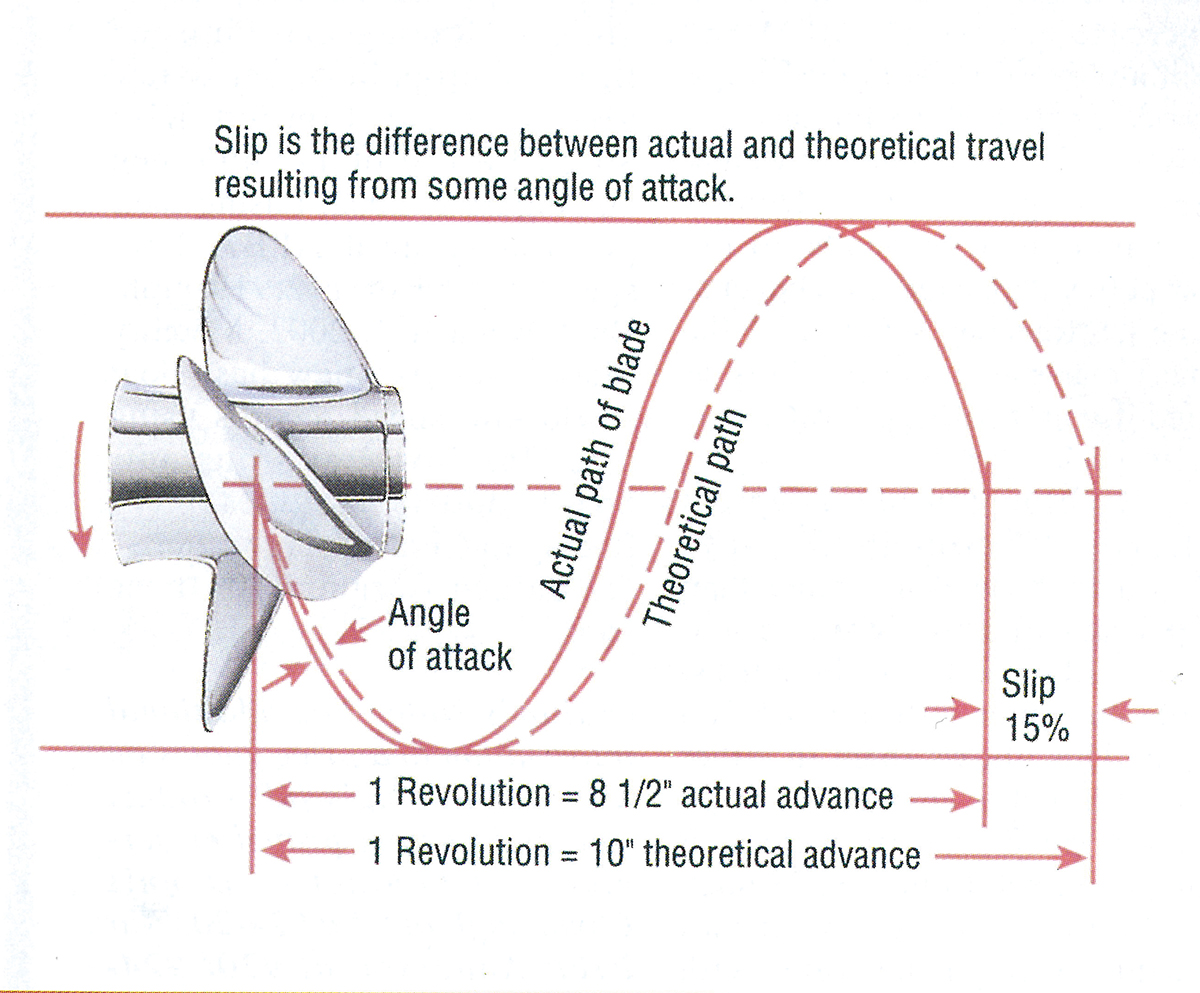

SLIP

Slip is the most understood of all propeller terms, probably because it sounds like something undesirable. Slip is not measure of propeller efficiency. Rather, slip is the difference between actual and theoretical travel resulting from a necessary propeller blade angle of attack.

For example, as the illustration shows, a 10” propeller actually advances only 8-1/2” in one revolution. Eight and one-half inches is 85 percent of 10 inches, leaving a slip of 15 percent. If the blade had no angle of attack – there would be no slip. But then again, there would be no positive or negative pressure created – and thus no thrust. The objective of propeller design is to achieve the right amount of slip or angle of attack which is around 4 degrees. This is accomplished by matching the right amount of blade diameter and blade area to the existing engine horsepower and propeller shaft RPM. Too much diameter or blade area will lower slip but will also lower propeller efficiency, resulting in reduced performance.

MERCURY RACING LAB FINISHEDTM PROPELLERS

Once you learn the basics of propeller design and function, you can feel confident purchasing propellers that will provide the correct size, pitch and rotation for your boat size, weight, horsepower and application. You can “dial in” your boat to run close to the maximum recommended engine operating RPM. But to really get the maximum performance out of your hull – you need to contact the Mercury Racing Propeller Lab.

Mercury Racing been producing custom high performance outboard and stern drive propellers since the early 1970s. Mercury Racing Lab FinishedTM props have set more speed records and won more national and world championships than any other propeller. Many of the first propellers was created and produced to support factory tunnel boat and offshore racing. In an effort to get more performance out of racing props, hydrodynamic experts spent years in engineering labs studying propellers travelling through water and the effects modifications made to propeller (and boat) performance. World renowned powerboat racers coined the term “Lab Finished” when referencing the custom Team Mercury propellers tweaked and modified in the Oshkosh, Wisconsin engineering lab. Team Mercury racers helped make “Lab Finished” a term known for record setting speed and performance around the world

Today, Mercury Racing continues to offer race and consumer Lab Finished propellers for custom outboard and sterndrive applications. Boaters can contact the company, describe their hull type, boat weight and power and the company’s experts will “dial-in” in a propeller (standard or Lab Finished) that will work best for their needs. Customers can also send in stock props to have them Lab Finished.

Mercury Racing can do everything except expand the diameter of a propeller. They can cut down the diameter, thin out the blades, increase and decrease pitch and modify cup. A multitude of adjustments can be made to increase or decrease RPM and enhance hole shot, midrange punch and overall performance.

“It’s all about power to weight and drag,” says the pros at Mercury Marine. “Our custom lab finishing services are the most reasonable and best way to find if your boat’s performance is at its peak.

“By blueprinting a typical Bravo 1 propeller,” says the late Denis Cavanaugh, who had more than 30 years of experience in and knowledge of hydrodynamics, “the customer will pick up 300 rpm. This allows them to either run at a higher engine rpm or go up one pitch size. By increasing the prop pitch from, say, 28 pitch to 30, the prop goes two inches farther through the water with each revolution, with the resultant increase in speed”.

Several tests, comparing a box stock Bravo 1 propeller against a Lab Finished version of the same propeller on the same boat, have proven the benefits of Mercury Racing’s services.

Keyword : Apba offshore racing, Mercury Marine, mercury racing, Nick Carter, Propeller, propeller blade Apba offshore racing, Mercury Marine, mercury racing, Nick Carter, Propeller, propeller blade