PBC’s tech expert Captain Bill Jennings offers some insightful prop talk to gain that extra speed and performance.

By Captain Bill Jennings

Your boat propeller is one of the most important elements in your boat’s drive train. The right boat propeller and your boating can be a joy. The wrong size and your boating will be miserable. Understanding your propeller is key to maximum performance and economy. In this article, we’ll review the parts and operating functions of a boat propeller, so you will have the knowledge you need to be a “prop pro”. Basic propeller terminology is really very simple but a prerequisite to finding the right prop for your boat.

water back, they create a vaccum on

the forward side of each blade, which pulls on the blade and moves the boat forward. This vacuum is so strong the extreme low-pressure area created can explode surface air bubbles with a force that can literally chip the paint off the prop.

Boat Propeller Size Matters:

Propeller sizes are identified with two numbers. The first number is the “diameter”. Diameter is measured in inches and is the number of inches from the tip of one blade to the centre of the hub, times two.If the distance on your prop from tip to centre is 7”, then your prop diameter number is 14. ‘Pitch’, is the theoretical distance, in inches, that a prop moves forward as cuts its way through one full revolution.If your prop is designed to move 21 inches forward with every full turn, then your pitch number is 21. if you have a prop with a diameter of 14 inches and a pitch of 21 inches, the part number for that prop would be “14 x 21”.The barrel shaped centre of your prop is called the ‘hub’. You prop attaches to your motor by sliding the hole in the hub, over the shaft on your motor, and locking it. Props for today’s outboards and sterndrives have passages within the hub through which the motor exhaust passes, while inboard yachts and working craft have separate exhausts, so there is no hub on their propellers.

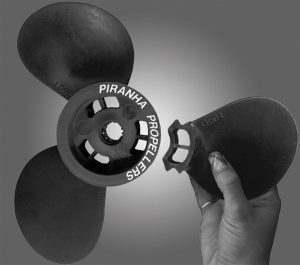

designed by Piranha Propellers, provide

boate rs with fast, inexpensive replacement

blades in the event of damage. It also allows the ability to experiment with different blade shapes on prop.

It is interesting to note that as prop blades spin and push water back, they also create a vacuum on the forward side of each blade. This vacuum pulls on the blade and is a major factor in moving the boat forward. This vacuum effect is so strong that the extreme low-pressure area created can sometimes suck in air (“ventilation”), and the force of the exploding air bubbles on the surface of the blade can chip paint off the prop. Don’t confuse this ventilation with “cavitation”, which is what occurs when the propeller spins from it’s own power, much like a car can spin its tires on a slippery road. The unmistakable symptom of both ventilation and cavitation is rapid over-revving. To correct this, you must reduce throttle, until the prop is able to reconnect with the water.

What about Blade Shapes?

Blades can be shaped in many different ways. The most common shape is the standard round ear or elliptical blade. These props deliver an optimum balance of thrust and speed. Tapered props create less drag and are used in higher speed applications. Almost all props today have what is called a cup, or curved lip, built into the trailing edge of each blade. A cup helps to flick water off the blade and increase speed. Think of a baseball pitcher’s pitch when he flicks his wrist as the ball leaves his hand. The improved thrust and grip reduces “slip”. Slip is a measure of the effectiveness of a propeller. For example, if a prop with a 25-inch pitch is rotated four complete rotations, it should theoretically move the boat forward 100 inches. If the boat only moves forward 90 inches, the prop is said to have a 10 percent slip.

If blades on a prop are perpendicular to the hub, the “rake” for that prop is zero. If the blades lean backwards, the prop is said to be a “raked” prop. The greater the lean the higher the rake. As a general rule, rake helps lift the bow and the higher degree of rake, the greater the bow lift. In this way, a propeller can be used to set the optimum running attitude of your boat. “Cleaver” props can be identified by their straight trailing edge. This shape keeps the water thrust low, allowing the blade tips to run at the surface without ventilating and also turn at higher RPM. A prop with blades that sweep in a curve and follow its rotation is called a “skewed” prop. This shape is ideal for props running through thick underwater growth, as they are less likely to tangle in weeds.

What about propeller materials? Bronze vs Aluminum vs Stainless vs Composite.

Early propellers were made of bronze and this material is still used today with hundreds of different sizes available to accommodate the wide variety of inboard applications. Over the last few years, Nickel has become a popular additive for strength and such props are called “Nibral”. Because of the hundreds of different sizes of Nibral props, finding one that is the right size for your boat is not easy to locate in the middle of boating season. It’s a good idea to have a spare on hand.

Aluminum props are relatively inexpensive, and generally supplied as original equipment on smaller horsepower applications. This cost factor, plus recent manufacturing improvements mean that aluminum props can work just fine for general boating scenarios. One misconception about aluminum is that they can be easily repaired. I personally do not recommend repairing aluminum, because when you heat it to bend it back into shape, or weld up tears, the prop changes in molecular structure and while it may look great, it is not as strong. You are better to buy a new prop and maybe move up to stainless.

Marine-grade stainless steel has become the preferred choice where strength and performance are desired. Since marine stainless steel is seven times stronger than aluminum, manufacturers are able to design their props thinner without sacrificing stiffness and strength. As you would expect, thinner blades cut through water more easily, with less drag. Run a stainless prop through sand or even coral and chances are, it will come through unscathed.

Not so with aluminum. Incidentally, unless you’re running a solid hub-racing prop, a prop strike with stainless will generally not damage your gears, as some people think. This is primarily due to the rubber hubs found in stainless as well as aluminum, that will spin or break if you do hit something. Stainless props come in a finish that is either “polished” or unpolished “satin”. Tests show that there is no performance difference between the two, but naturally, polished stainless will cost considerably more.

Keep in mind that companies are always trying to improve their propellers. A new company called ‘Sharrow Propellers’ has come up with a propeller using looped blades quite effectively. If they can produce the large number of sizes required they may be leading us to the next generation of props.

A more recent material used to manufacture propellers is high tech composite. With today’s advanced resins, nylon and carbon fibers, we see extensive use of composites used throughout the marine and aviation industry. In addition to having greater strength than aluminum, composite propellers won’t corrode or blister and many offer a lifetime hub warranty. Some offer individually replaceable blades and composite prices are less than aluminum. Performance tests for composite props vary, with some composites being faster than aluminum and some not.

How Many Blades Do I Need

One of the most frequent questions I am asked is “Do I need a three or four bladed prop?” While there is no fixed rule, this explanation will help. As you increase blade size or add blades, you increase what is called the “Diameter Area Ratio”. In other words, the relativity of the area of prop blades within the circle area that the propeller cuts. While larger blades add drag, they also provides a larger surface area that is pushing your boat. Think of wider tires on a car and you’ll have a good comparison. More grip, but harder to turn. Since blades create drag, your starting point should be as few blades as possible, with the minimum of course being two.

Over the past several years the average horsepower in boats has increased and boat manufacturers have created new ways to reduce wetted surface drag by using lighter materials, composites and incorporating “steps” in the bottom of hulls. These techniques opened the door to four and five bladed propellers. If your boat and horsepower can handle a four-bladed prop, you’ll enjoy several benefits. A four-bladed prop always has the same number of blades pointing up as it does down, providing smoother operation, quicker acceleration from idle, and a slower minimum planing speed

When faced with a decision between a 3 and 4 bladed prop, the only sure way to choose is to try both. However, from my experience, if your boat is over 28’, or heavy when loaded, or you participate in tow sports, it will perform best with a four-bladed prop since the added drag is offset by the added thrust. Aside from these situations, stay with a three-bladed prop and save your money

In the second instalment of Propellers 101, we’ll take a look at a comprehensive test using propellers from many different manufacturers and report how each manufacturer faired. We’ll also provide a step-by-step guide of how you can calculate the best size of prop for your boat.

Keyword : Aluminum propellers, Boating, boating magazine, Bronze propeller, buying new outboards, Composite propeller, engine review, marine power, Mercury, Mercury Marine, Mercury Verado, new motors, outboard reviews, outboards, power tech msqa, propeller blades, propellers, props, sharrow propellers, Stainless propellers, upgrading boat engine Aluminum propellers, Boating, boating magazine, Bronze propeller, buying new outboards, Composite propeller, engine review, marine power, Mercury, Mercury Marine, Mercury Verado, new motors, outboard reviews, outboards, power tech msqa, propeller blades, propellers, props, sharrow propellers, Stainless propellers, upgrading boat engine